metal keyboard

Source: 本站 Published: 2023/10/18

The technology of computer keyboards includes many elements. Among the more important of these is the switch technology that they use. Computer alphanumeric keyboards typically have 80 to 110 durable switches, generally one for each key. The choice of switch technology affects key response (the positive feedback that a key has been pressed) and pre-travel (the distance needed to push the key to enter a character reliably). Virtual keyboards on touch screens have no physical switches and provide audio and haptic feedback instead. Some newer keyboard models use hybrids of various technologies to achieve greater cost savings or better ergonomics.

The modern keyboard also includes a control processor and indicator lights to provide feedback to the user (and to the central processor) about what state the keyboard is in. Plug-and-play technology means that its "out of the box" layout can be notified to the system, making the keyboard immediately ready to use without the need for further configuration, unless the user so desires.

Types[edit]

Membrane keyboard[edit]

There are two types of membrane-based keyboards, flat-panel membrane keyboards and full-travel membrane keyboards:

Flat-panel membrane keyboards are most often found on appliances like microwave ovens or photocopiers. A common design consists of three layers. The top layer has the labels printed on its front and conductive stripes printed on the back. Under this, it has a spacer layer, which holds the front and back layers apart so that they do not normally make electrical contact. The back layer has conductive stripes printed perpendicularly to those of the front layer. When placed together, the stripes form a grid. When the user pushes down at a particular position, their finger pushes the front layer down through the spacer layer to close a circuit at one of the intersections of the grid. This indicates to the computer or keyboard control processor that a particular button has been pressed.

Generally, flat-panel membrane keyboards do not produce noticeable physical feedback. Therefore, devices using these issue a beep or flash a light when the key is pressed. They are often used in harsh environments where water- or leak-proofing is desirable. Although used in the early days of the personal computer (on the Sinclair ZX80, ZX81 and Atari 400), they have been supplanted by the more tactile dome and mechanical switch keyboards.

Full-travel membrane-based keyboards are the most common computer keyboards today. They have one-piece plastic keytop/switch plungers that press down on a membrane to actuate a contact in an electrical switch matrix.

Dome-switch keyboard[edit]

Dome-switch keyboards are a hybrid of flat-panel membrane and mechanical-switch keyboards. They bring two circuit board traces together under a rubber or silicone keypad using either metal "dome" switches or polyurethane formed domes. The metal dome switches are formed pieces of stainless steel that, when compressed, give the user crisp, positive tactile feedback. These metal types of dome switches are very common, are usually reliable to over 5 million cycles, and can be plated in either nickel, silver or gold. The rubber dome switches, occasionally referred to as polydomes, are formed polyurethane domes where the inside bubble is coated in graphite.

While polydomes are typically cheaper than metal domes, they lack the crisp snap of the metal domes and usually have a lower life specification. Polydomes are considered very quiet, but purists tend to find them "mushy" because the collapsing dome does not provide as much crisp, positive response as metal domes. For either metal or polydomes, when a key is pressed, it collapses the dome, which connects the two circuit traces and completes the connection to enter the character. The pattern on the PC board is often gold-plated.

Both are common switch technologies used in mass-market keyboards today. This type of switch technology happens to be most commonly used in handheld controllers, mobile phones, automotive, consumer electronics and medical devices. Dome-switch keyboards are also called direct-switch keyboards.

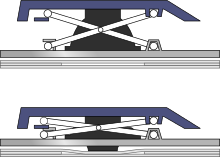

Scissor-switch keyboard[edit]

A special case of the computer keyboard dome-switch is the scissor-switch. The keys are attached to the keyboard via two plastic pieces that interlock in a "scissor"-like fashion and snap to the keyboard and the key. It still uses rubber domes, but a special plastic 'scissors' mechanism links the keycap to a plunger that depresses the rubber dome with a much shorter travel than the typical rubber dome keyboard. Typically scissor-switch keyboards also employ 3-layer membranes as the electrical component of the switch. They also usually have a shorter total key travel distance (2 mm instead of 3.5–4 mm for standard dome-switch keyswitches). This type of keyswitch is often found on the built-in keyboards on laptops and keyboards marketed as 'low-profile'. These keyboards are generally quiet and the keys require little force to press.

Scissor-switch keyboards are typically slightly more expensive. They are harder to clean (due to the limited movement of the keys and their multiple attachment points) but also less likely to get debris in them as the gaps between the keys are often smaller (as there is no need for extra room to allow for the 'wiggle' in the key, as typically found on a membrane keyboard).[1]

Capacitive keyboard[edit]

In this type of keyboard, pressing a key changes the capacitance of a pattern of capacitor pads. The pattern consists of two D-shaped capacitor pads for each switch, printed on a printed circuit board (PCB) and covered by a thin, insulating film of soldermask which acts as a dielectric.

Despite the sophistication of the concept, the mechanism of capacitive switching is physically simple. The movable part ends with a flat foam element about the size of an aspirin tablet, finished with aluminum foil. Opposite the switch is a PCB with the capacitor pads. When the key is pressed, the foil tightly clings to the surface of the PCB, forming a daisy chain of two capacitors between contact pads and itself separated with a thin soldermask, and thus "shorting" the contact pads with an easily detectable drop of capacitive reactance between them. Usually, this permits a pulse or pulse train to be sensed. Because the switch does not have an actual electrical contact, there is no debouncing necessary.

The keys do not need to be fully pressed to be actuated, which enables some people to type faster. The sensor tells enough about the position of the key to allow the user to adjust the actuation point (key sensitivity). This adjustment can be done with the help of the bundled software and individually for each key, if so implemented.[2]

The IBM Model F keyboard is mechanical-key design consisting of a buckling spring over a capacitive PCB, similar to the later Model M keyboard that used a membrane in place of the PCB.

The Topre Corporation design for key switches uses a spring below a rubber dome. The dome provides most of the force that keeps the key from being pressed, similar to a membrane keyboard, while the spring helps with the capacitive action.[3]

Mechanical-switch keyboard[edit]

Every key on a mechanical-switch keyboard contains a complete switch underneath. Each switch is composed of a housing, a spring, and a stem, and sometimes other parts such as a separate tactile leaf or a clickbar. Switches come in three variants: "linear" with consistent resistance, "tactile" with a non-audible bump, and "clicky" with both a bump and an audible click.[4][5] Depending on the resistance of the spring, the key requires different amounts of pressure to actuate and to bottom out. The shape of the stem as well as the design of the switch housing varies the actuation distance and travel distance of the switch.

The sound can be altered by the material of the plate, case, lubrication, the keycap profile, and even modifying the individual switch. These modifications, or "mods" include applying lubricant to reduce friction inside the switch itself, inserting "switch films" to reduce wobble, swapping out the spring inside to modify the resistance of the switch itself and many more.[6] Mechanical keyboards allow for the removal and replacement of keycaps with a common stem type.

Alongside the mechanical keyboard switch is the stabilizer, which supports longer keys such as the "spacebar", "enter", "backspace", and "shift" keys. Although these are not as diverse as switches, they come in different sizes. These different sizes are designed for keyboards that are longer than normal. Similar to a mechanical keyboard switch, the stabilizer can be modified to alter the sound and feel of these certain keys. Lubricant can be used to reduce the rattle of the metal wire that makes up a stabilizer. Furthermore, implementing padding in the "housing" of the stabilizer will lessen rattle and improve acoustics.[7]

Mechanical keyboards typically have a longer lifespan than membrane or dome-switch keyboards. [8]

A major producer of mechanical switches is Cherry, who has manufactured the MX family of switches since the 1980s. Cherry's color-coding system of categorizing switches has been imitated by other mechanical switch manufacturers, such as Gateron and Kailh among many others.[9][10]

Hot-swappable keyboard[edit]

|

This section needs additional citations for verification. (May 2021)

|

Hot-swappable keyboards are keyboards where switches can be pulled out and replaced rather than requiring the typical solder connection.[11][12] Instead of the switch being soldered to the keyboard's PCB, hot-swap sockets are instead soldered on. They are mostly used by keyboard enthusiasts that build custom keyboards,[citation needed] and have recently begun being adopted by larger companies on production keyboards.[citation needed] Hot-swap sockets can allow users to try a variety of different switches without having the tools or knowledge required to solder electronics.

Buckling-spring keyboard[edit]

Many typists prefer buckling spring keyboards.[13] The buckling spring mechanism (expired U.S. Patent 4,118,611) atop the switch is responsible for the tactile and aural response of the keyboard. This mechanism controls a small hammer that strikes a capacitive or membrane switch.[14]

In 1993, two years after spawning Lexmark, IBM transferred its keyboard operations to the daughter company. New Model M keyboards continued to be manufactured for IBM by Lexmark until 1996, when Unicomp was established and purchased the keyboard patents and tooling equipment to continue their production.

IBM continued to make Model M's in their Scotland factory until 1999.[15]

Hall-effect keyboard[edit]

Hall effect keyboards use magnets and Hall effect sensors instead of switches with mechanical contacts. When a key is depressed, it moves a magnet that is detected by a solid-state sensor. Because they require no physical contact for actuation, Hall-effect keyboards are extremely reliable and can accept millions of keystrokes before failing. They are used for ultra-high reliability applications such as nuclear power plants, aircraft cockpits, and critical industrial environments. They can easily be made totally waterproof, and can resist large amounts of dust and contaminants. Because a magnet and sensor are required for each key, as well as custom control electronics, they are expensive to manufacture.

A hall switch works through magnetic fields. Every switch has a small magnet fixed inside it. When the electricity passes through the main circuit, it creates a magnetic flux. So, every time you press a key, the magnetic intensity changes. This change is noted by the circuit and the sensors send the information to the motherboard.[16]

Laser projection keyboard[edit]

A laser projection device approximately the size of a computer mouse projects the outline of keyboard keys onto a flat surface, such as a table or desk. This type of keyboard is portable enough to be easily used with PDAs and cellphones, and many models have retractable cords and wireless capabilities. However, sudden or accidental disruption of the laser will register unwanted keystrokes. Also, if the laser malfunctions, the whole unit becomes useless, unlike conventional keyboards which can be used even if a variety of parts (such as the keycaps) are removed. This type of keyboard can be frustrating to use since it is susceptible to errors, even in the course of normal typing, and its complete lack of tactile feedback makes it even less user-friendly than the lowest quality membrane keyboards.

Roll-up keyboard[edit]

Copyright © Ningbo ChenTe Electronics Technologies co.,Ltd

Add :No 6. First Rd, Western Industrial Park,Lubu town, Yuyao Zhejiang 315420 China